OUR PRODUCTS

Corrosion Monitoring

Our Corrosion Monitoring Service aims to extend the lifespan of industrial assets, minimize

downtime, and enhance overall operational reliability by proactively addressing corrosion

challenges. Through a combination of cutting-edge technology and industry expertise

by our strategic partner AXESS Corrosion, we provide a tailored approach to corrosion

management for a variety of industrial applications.

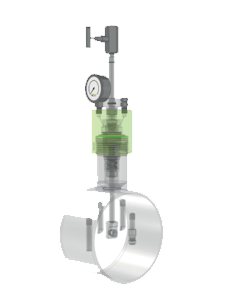

Injection & Sampling

Whilst many injection and sampling systems

can only be serviced and maintained during

shutdown conditions Axess provides a range of

high and low-pressure injection and sampling

systems which can be serviced safely online at

pressures up to 6,000 PSI / 413 Bar and temperatures

up to 232°C / 450°F.

Direct Injection

Chemical Injection & Sampling

Corrosion & Erosion

Axess offers a full range of hardware for the insertion and retrieval of monitoring, injection

and sampling devices (Intrusive Monitoring Techniques) and Non-intrusive wall thickness

solutions provide in-service corrosion and erosion monitoring (Non-Intrusive Sensors).

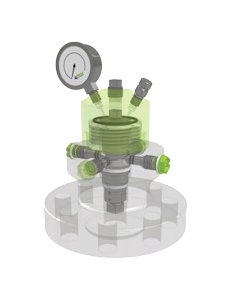

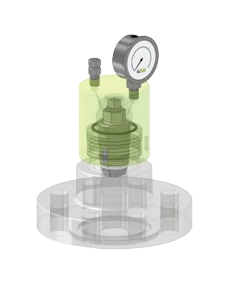

High Pressure Hydraulic Access Fitting System

Provides a complete solution for the online safe, reliable installation of probes and coupons from high pressure piping, and vessels at pressures of up to 6,000 PSI (414 Bar) and temperatures up to 204°C (400°F).

High Pressure Mechanical Access Fitting System

Provides a complete solution for the online safe, reliable installation of probes and coupons from high pressure piping, and vessels at pressures of up to 6,000 PSI (414 Bar) and temperatures up to 204°C (400°F).

High Pressure Retrieval Equipment

Used to safely and e ciently insert and retrieve probes, coupons, sensors, and chemical injection devices from a process under full operating conditions and pressures. We manufacture hydraulic, mechanical and dual use version retrievers with Janus™ technology